Intravenous fluid bags are filled by an automated filling machine – Intravenous fluid bags are filled by automated filling machines, a revolutionary technology that has transformed the production of these essential medical supplies. These machines offer a multitude of advantages, including increased efficiency, enhanced accuracy, and improved sterility, making them indispensable in modern healthcare settings.

The automated filling process involves several key steps, each meticulously controlled to ensure the highest quality standards. Advanced equipment and sophisticated technology work in harmony to fill the bags with precision, while rigorous quality control measures safeguard the integrity of the final product.

Automated Filling Machine Processes

Automated filling machines streamline the process of filling intravenous fluid bags, enhancing efficiency and accuracy. These machines employ a series of automated steps to ensure consistent and precise filling.

Equipment and Technology

Automated filling machines typically consist of a conveyor system, filling heads, and a control panel. The conveyor system transports the bags through the filling process, while the filling heads dispense the fluid into the bags. The control panel allows operators to monitor and adjust the filling parameters.

Advantages of Automation

- Increased accuracy and consistency in filling

- Reduced labor costs and improved productivity

- Enhanced product quality and reduced risk of contamination

Disadvantages of Automation

- Higher initial investment cost

- Potential for downtime due to maintenance or technical issues

- Limited flexibility compared to manual filling

Quality Control Measures

Quality control is crucial in the automated filling of intravenous fluid bags to ensure the accuracy and sterility of the products. Several measures are implemented to maintain high standards.

Testing Methods

- Fill volume testing:Verifies the accuracy of the fluid volume dispensed into each bag.

- Leak testing:Detects any leaks or punctures in the bags after filling.

- Sterility testing:Ensures the absence of microorganisms in the filled bags.

Aseptic Conditions

Maintaining aseptic conditions throughout the filling process is paramount to prevent contamination. This includes using sterile equipment, HEPA filters, and cleanroom environments.

Efficiency and Productivity

Automated filling machines significantly enhance efficiency and productivity compared to manual filling. They can fill a large number of bags quickly and consistently, reducing production timelines.

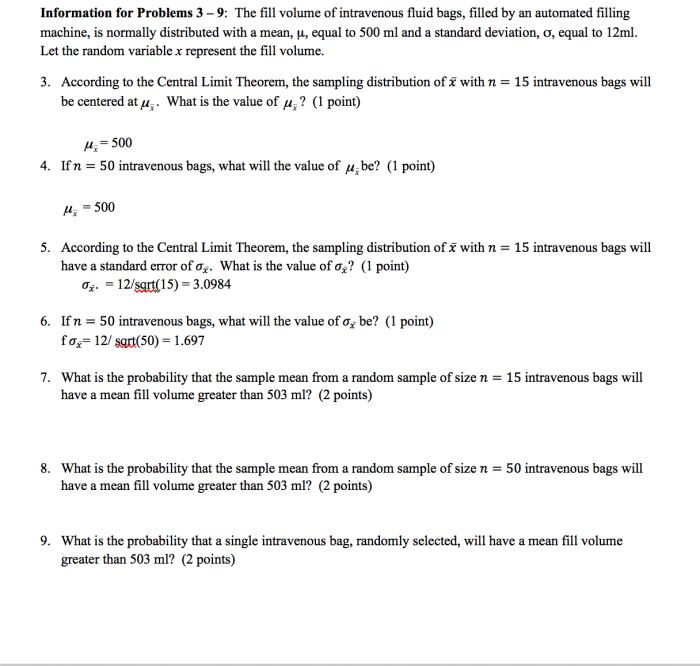

Data and Examples

- A study by a leading manufacturer showed that an automated filling machine can fill up to 1,200 bags per hour, while manual filling typically achieves 200-300 bags per hour.

- The reduced labor costs and increased productivity lead to overall cost-effectiveness in production.

Potential for Optimization, Intravenous fluid bags are filled by an automated filling machine

Continuous advancements in technology provide opportunities for further optimization. Integrating robotics, AI, and data analytics can enhance accuracy, efficiency, and quality control.

Safety Considerations: Intravenous Fluid Bags Are Filled By An Automated Filling Machine

Safety is a top priority in the automated filling of intravenous fluid bags. Potential hazards include:

Hazard Mitigation

- Pinch points:Guards and safety mechanisms prevent operators from getting caught in moving parts.

- Electrical hazards:Proper grounding and insulation ensure electrical safety.

- Fluid spills:Spill containment systems and proper handling techniques minimize the risk of fluid spills.

Regulatory Standards

Automated filling machines must comply with regulatory standards and guidelines to ensure safe operation. These standards include:

- ISO 13485:2016

- FDA 21 CFR Part 820

Future Trends and Innovations

The future of intravenous fluid bag filling holds exciting prospects for technological advancements and innovation.

Emerging Technologies

- Artificial intelligence (AI):AI algorithms can optimize filling parameters and predict potential issues.

- Robotics:Collaborative robots can assist with bag handling and quality control.

- Data analytics:Data collection and analysis can provide insights for process improvement and predictive maintenance.

Sustainability and Environmental Considerations

Sustainability is becoming increasingly important in the design and operation of automated filling machines. This includes using energy-efficient components, reducing waste, and employing eco-friendly materials.

Q&A

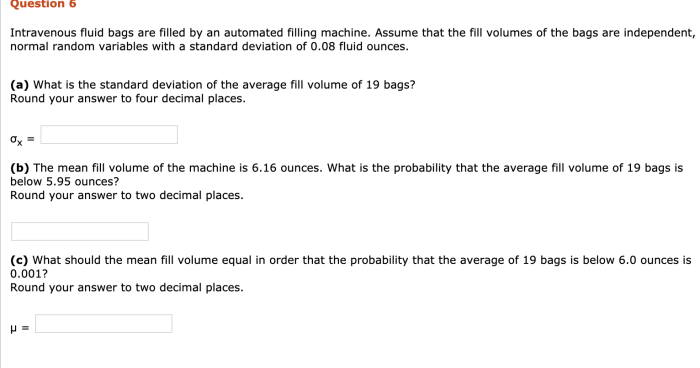

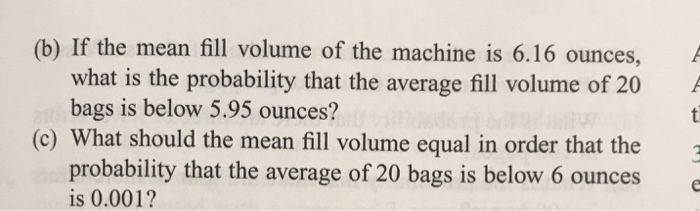

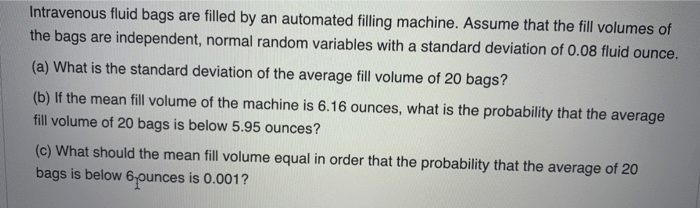

How do automated filling machines ensure the accuracy of intravenous fluid bags?

Automated filling machines employ precise measurement systems and advanced sensors to dispense the exact amount of fluid into each bag, ensuring consistent and accurate dosing.

What quality control measures are implemented during the automated filling process?

Quality control measures include rigorous testing to verify the integrity of the bags, sterility checks to prevent contamination, and visual inspections to detect any defects.

How do automated filling machines contribute to increased efficiency in intravenous fluid bag production?

Automated filling machines operate at high speeds, reducing production time and labor costs. They also eliminate manual errors, leading to improved overall efficiency.